HIGG FEM AND FSLM MANAGEMENT SYSTEM

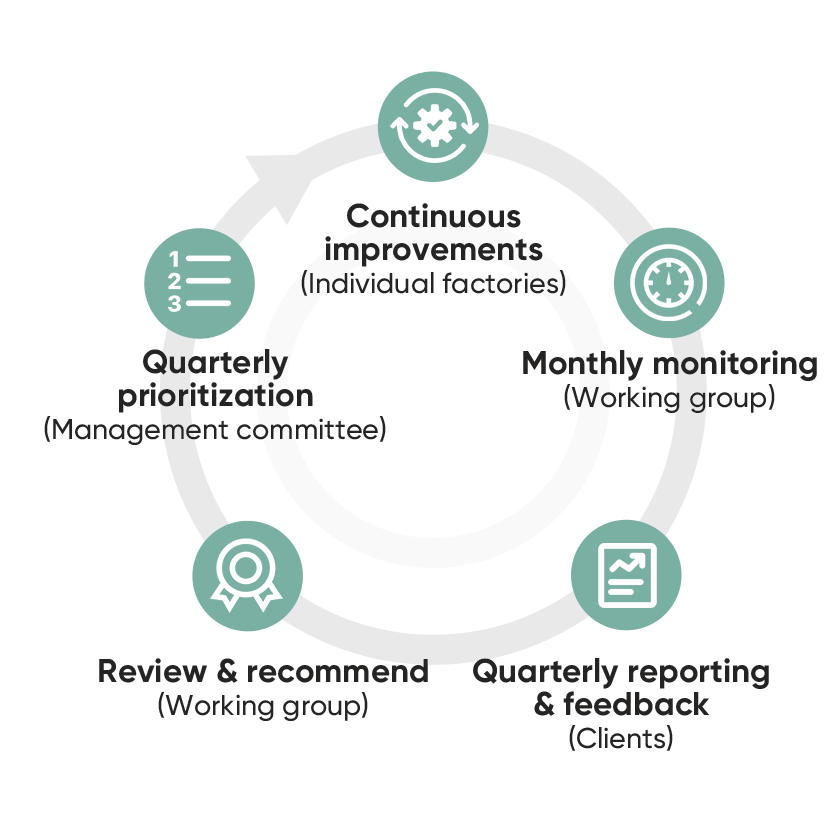

We have chosen to use the Higg Facility Environmental Module (FEM) and Facility Social & Labor Module (FSLM) as our central management system to identify impact hot spots and set our targets accordingly.

We believe that this is the best way to share our progress and data with our customers so that you don’t have to take our word for it, you can benchmark our progress with our historic performance and with other industry players. We have identified two key measurements, accuracy and efficiency.

Accuracy: We want to ensure our teams have a good understanding of the self-assessment, currently our average accuracy for FEM is 89%. This means that we have room to improve our common understanding of our sustainability context. Our objective is to have 100% accuracy in our self-assessment after it has undergone verification.

Efficiency: Our objective is to reach a robust 45 points in Higg FEM for our top factories for our 2024 assessment, and a robust 70 points in the 2025 assessment. For FSLM, our goal in 2024 is to align all factories to adopt the assessment system, and reach a robust 75 points for our 2025 assessment.